Introduction

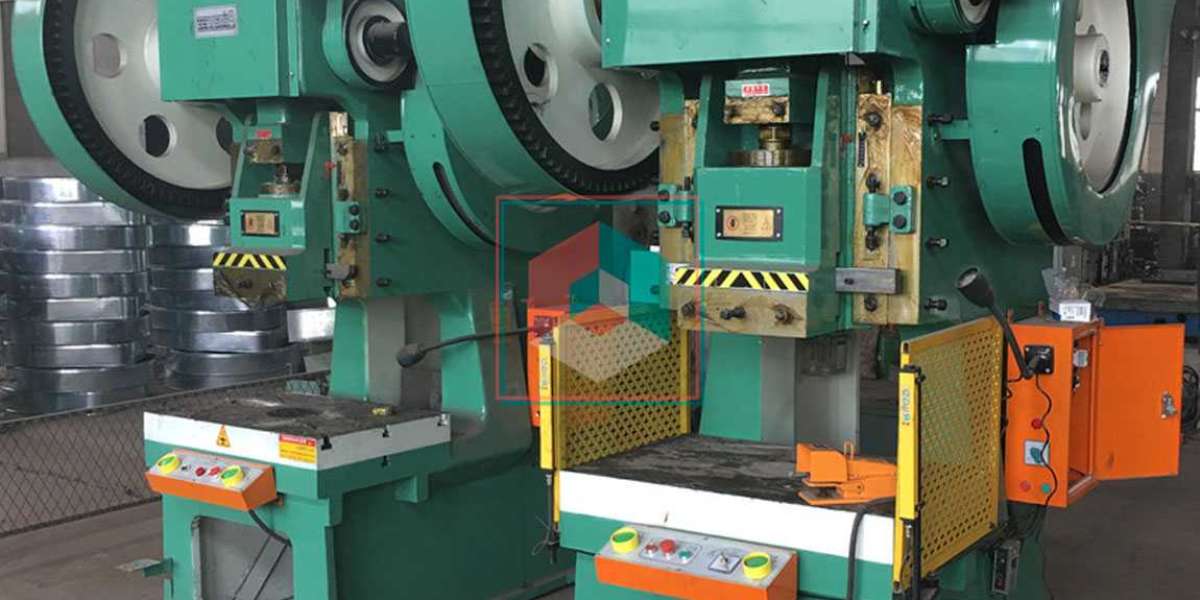

The Press Machine Market is a fundamental segment of the industrial machinery landscape, supplying equipment used to shape, cut, bend, punch, and assemble metal and other materials through the application of mechanical, hydraulic, or servo-driven force. Press machines are widely used across automotive, aerospace, electrical and electronics, construction, appliances, packaging, and general manufacturing industries. These machines enable mass production of components with high accuracy, consistency, and productivity. As global manufacturing continues to evolve toward automation, lightweight materials, and precision engineering, press machines remain indispensable to modern industrial operations.

Market Drivers

One of the primary drivers of the Press Machine Market is the continued growth of manufacturing and industrial production. Sectors such as automotive, consumer electronics, and industrial equipment rely heavily on press machines for stamping body panels, structural parts, brackets, connectors, and enclosures. Rising demand for vehicles, appliances, and electronic products directly supports the need for high-capacity and high-speed press machinery.

Automation and productivity enhancement are also major growth drivers. Manufacturers are under constant pressure to reduce cycle times, improve quality, and minimize labor costs. Modern press machines equipped with automation, robotic handling systems, and advanced control software enable higher throughput and repeatable precision. This makes press machines a key investment in smart factories and high-volume production environments.

The shift toward lightweight and advanced materials further drives market growth. Automotive and aerospace manufacturers increasingly use high-strength steel, aluminum alloys, and composite materials to improve fuel efficiency and performance. Press machines with higher tonnage, better control, and advanced tooling are required to process these materials effectively, supporting demand for next-generation press systems.

Market Challenges

Despite strong demand, the Press Machine Market faces several challenges. High capital investment is a major barrier, particularly for large hydraulic, mechanical, and servo presses. Small and medium-sized manufacturers may find it difficult to justify the upfront cost of advanced press machines, slowing adoption in cost-sensitive markets.

Maintenance and downtime also present challenges. Press machines operate under high stress and require regular maintenance to ensure accuracy, safety, and reliability. Unplanned downtime can lead to significant production losses, increasing the importance of skilled operators and maintenance personnel.

Safety and regulatory compliance add further complexity. Press machines pose inherent safety risks, and manufacturers must comply with strict safety standards related to guarding, emergency stops, and operator protection. Meeting these requirements can increase equipment cost and installation complexity.

Market Opportunities

Technological advancement presents significant opportunities for the Press Machine Market. Servo-driven press machines are gaining popularity due to their superior energy efficiency, precise force control, and programmable motion profiles. These machines allow manufacturers to optimize forming processes, reduce energy consumption, and improve part quality, making them attractive for advanced manufacturing applications.

Integration with digital technologies also creates new growth opportunities. Press machines equipped with sensors, data analytics, and connectivity support predictive maintenance, real-time monitoring, and process optimization. These capabilities align with Industry 4.0 initiatives and help manufacturers improve equipment utilization and reduce operating costs.

Emerging markets offer additional growth potential. Rapid industrialization, infrastructure development, and expansion of automotive and electronics manufacturing in regions such as Asia-Pacific, Latin America, and parts of Africa are driving demand for press machines. Local manufacturing initiatives and foreign direct investment further support market expansion.

Regional Insights

Asia-Pacific dominates the Press Machine Market, driven by large-scale manufacturing activity, strong automotive and electronics production, and expanding industrial infrastructure. Countries such as China, Japan, South Korea, and India are major contributors, with significant demand for both conventional and advanced press machines.

Europe represents a mature but technology-driven market. The region emphasizes high-precision, energy-efficient, and automated press solutions, particularly for automotive, aerospace, and industrial equipment manufacturing. Germany and Italy are key hubs for press machine innovation and production.

North America shows steady growth, supported by automotive manufacturing, metal fabrication, and increasing adoption of automation and smart manufacturing technologies. Demand is largely driven by equipment upgrades and replacement of older machinery.

Other regions, including the Middle East and Latin America, are gradually expanding their manufacturing base, contributing to long-term demand for press machines.

Future Outlook

The Press Machine Market is expected to grow steadily as global manufacturing activity expands and production processes become more automated and data-driven. Demand will increasingly shift toward energy-efficient, flexible, and digitally enabled press machines that support a wide range of materials and applications.

Manufacturers will focus on developing machines with higher precision, lower energy consumption, and improved safety features. Servo press technology, modular designs, and advanced control systems will play a key role in meeting evolving customer requirements.

As sustainability becomes a priority, press machines that reduce material waste, energy usage, and emissions will gain competitive advantage. This trend will further shape product development and purchasing decisions in the market.

Conclusion

The Press Machine Market remains a cornerstone of modern manufacturing, enabling high-volume and high-precision production across multiple industries. Driven by industrial growth, automation, and demand for advanced materials processing, the market offers strong long-term potential. While challenges related to cost, maintenance, and safety exist, ongoing technological innovation and expansion in emerging markets are strengthening the role of press machines in the global manufacturing ecosystem.