As per Market Research Futute, the Pneumatic Components Market is witnessing substantial growth, driven by the increasing demand for automation and efficient industrial processes. Pneumatic fittings, an essential part of pneumatic systems, play a critical role in connecting various components like tubes, valves, and actuators to ensure smooth operation. These fittings are designed to withstand high pressure, provide leak-proof connections, and facilitate easy installation and maintenance. As industries continue to adopt automation technologies, the significance of high-quality pneumatic fittings has never been more pronounced.

Pneumatic fittings are available in a variety of types, each catering to specific industrial needs. Push-to-connect fittings, elbow fittings, T-fittings, and bulkhead fittings are some of the most commonly used types in industrial applications. Push-to-connect fittings, for instance, allow for quick and effortless connections and disconnections of tubes without the need for additional tools. This feature is particularly valuable in industries where frequent maintenance or reconfiguration of pneumatic systems is required. Elbow and T-fittings, on the other hand, are essential for directing the flow of compressed air and creating complex network pathways.

Material selection plays a crucial role in the performance of pneumatic fittings. These fittings are typically manufactured from metals like brass, stainless steel, and aluminum, as well as high-quality plastics such as nylon and polypropylene. Brass fittings are known for their durability and resistance to corrosion, making them suitable for harsh industrial environments. Stainless steel fittings are preferred in industries that demand high strength and hygiene standards, such as pharmaceuticals and food processing. Plastic fittings, while lightweight and cost-effective, are widely used in applications with moderate pressure requirements.

The global market for pneumatic fittings is being fueled by several factors. The growing automation in manufacturing industries, particularly in automotive, electronics, and packaging sectors, has led to increased adoption of pneumatic systems. These systems offer energy efficiency, precision, and reliability, making them a preferred choice over hydraulic or purely mechanical systems in many applications. Additionally, the rise of Industry 4.0 and smart factories is encouraging the integration of advanced pneumatic components that are compatible with IoT-based monitoring and control systems.

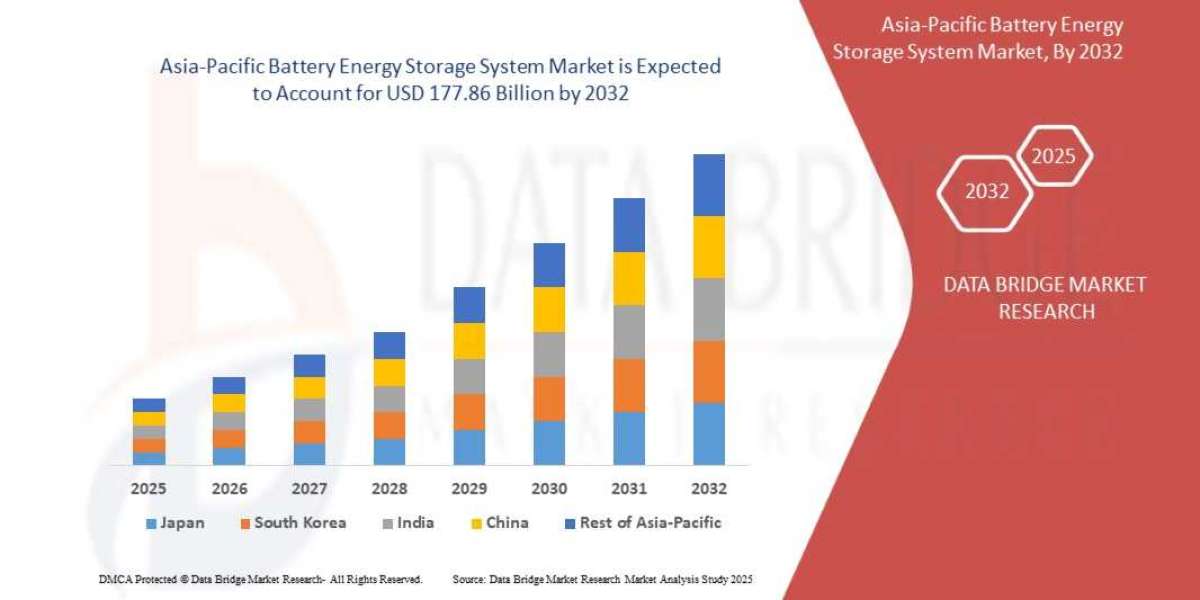

Regionally, Asia-Pacific dominates the pneumatic fittings market, driven by rapid industrialization and the presence of key manufacturing hubs in countries like China, Japan, and India. Europe and North America also represent significant markets due to the demand for high-quality pneumatic components and the adoption of automation technologies in manufacturing. The competitive landscape is characterized by established players focusing on product innovation, strategic partnerships, and expansion into emerging markets to strengthen their market presence.

Emerging trends in the pneumatic fittings market include the development of compact and lightweight fittings that enhance space utilization and reduce overall system weight. Smart pneumatic fittings equipped with sensors for real-time monitoring of pressure, flow, and leakage are gaining traction, offering predictive maintenance capabilities and improving system efficiency. Environmental sustainability is another focus area, with manufacturers increasingly using eco-friendly materials and optimizing production processes to reduce carbon footprints.

In conclusion, pneumatic fittings are indispensable components in modern industrial systems, contributing significantly to operational efficiency and reliability. As industries continue to embrace automation and advanced technologies, the demand for high-quality, innovative, and durable pneumatic fittings is expected to grow steadily. Companies that invest in research, product development, and smart solutions are well-positioned to capitalize on the expanding opportunities in the global pneumatic fittings market.

FAQs

Q1: What are pneumatic fittings used for?

A1: Pneumatic fittings are used to connect various components of a pneumatic system, such as tubes, valves, and actuators, ensuring efficient and leak-proof transmission of compressed air.

Q2: What materials are commonly used in pneumatic fittings?

A2: Pneumatic fittings are commonly made from brass, stainless steel, aluminum, and high-quality plastics like nylon and polypropylene, each selected based on durability, corrosion resistance, and application requirements.

Q3: Which industries have the highest demand for pneumatic fittings?

A3: Industries such as automotive, electronics, packaging, pharmaceuticals, and food processing have high demand due to their reliance on automated and precise pneumatic systems.

More Related Reports: